Red River Paper Blog

Best Places to Take Pictures in El Paso: From Historical Buildings to Nature

Stuck at the extreme western point of the state of Texas, El Paso is too often forgotten as a photo destination. Yet it offers an amazing nexus of Hisopanic culture, Old West history, varied architecture, and mdern convenience....read more

Success on Paper: Michael Rung, Nature and Landscape Photographer

See how Michael Rung started his landscape photography business — and took it next-level with elegant, archival print paper....read more

Success on Paper: Priscilla Lee, Fantasy Artist

Mermaids, magic, and mythology come to life through Priscilla Lee’s watercolors. Can prints replicate the intricacy of her work?...read more

Archival Photo Paper: What It Is and When to Use It

What exactly do we mean by “archival paper”? For the full scoop on what it is and when to use it, read on...read more

Success on Paper: Ron E. Gross, Photographer & Digital Artist

When his art sales rose 100%, Florida photographer and digital artist Ron E. Gross was quick to give Red River Paper credit....read more

Never miss a post again and get exclusive savings offers. Signup to Red River Paper's Newsletter!

How to Print on Glossy Photo Paper

Want your prints to be as bold and bright as possible? Glossy photo paper is the way....read more

Success on Paper: Jesse Thornton, Landscape Photographer

When you’re photographing land and sky (and tight-rope walkers against a full moon!), patience is required. So is high-quality paper and printing advice....read more

Success on Paper: Kevin Raber, Photographer & Fine Art Printer

From penguins in Antarctica to barns in the Palouse, Kevin Raber has a unique view of the world. See how we help this Indianapolis photographer display and sell his work....read more

Borderless Printing: How to Print Full Page Without a White Border

Printing your artwork full page, sans borders, is a dynamic look. But how to do it?...read more

Success on Paper: Deanna Camp, Graphic Designer & Fine Artist

See how we help Northwest artist Deanna Camp create fantastical fish tales — and catch more customers....read more

How to Color Calibrate Your Prints to Your Monitor

You may think think your monitor is accurately displaying the exact colors that are in your image file, but it may not, leading to prints with disturbing color casts. Here's how to fix that problem....read more

Never miss a post again and get exclusive savings offers. Signup to Red River Paper's Newsletter!

How to Print Postcards at Home

Printing postcards at home is a delightful way to share memories, create personalized invitations, or even design promotional materials for your small business....read more

Success on Paper: Danny Izzo, Photographer

Marching bands and Mardi Gras krewes are a unique portrait niche that require a distinct solution for prints. See how we helped Louisiana-based photographer Danny Izzo showcase these large groups beautifully....read more

Success on Paper: Cindy Baird, Watercolor Artist

Watercolor artist Cindy Baird worried that prints wouldn’t do her paintings justice. Then she found us....read more

What is Fiber-Based Photo Paper?

Many photographers seek photo paper with a certain weight and thickness, a smooth finish, and archival quality. Fiber-based photo paper fits the bill....read more

Success on Paper: Why We Share These Tales of Triumph

When you run a business that supports creative people, you’re guaranteed to be awestruck most days. Learn about the inspiraton behind our Success on Paper Series....read more

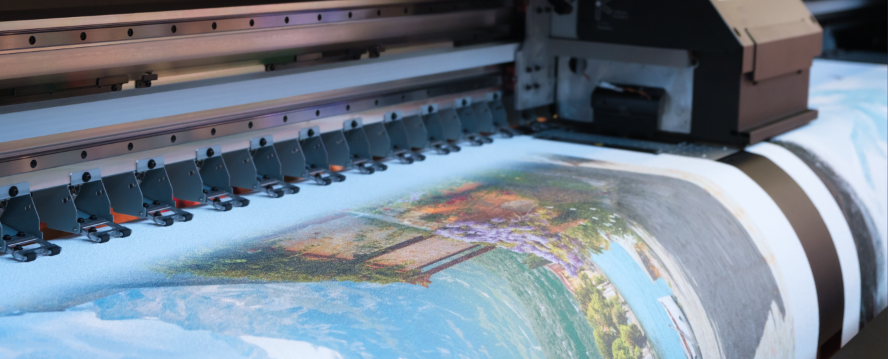

Types of Printers: What Each Different Type is Best For

Here's a comprehensive guide to the various types of printers available in the market....read more